Watch this short Palladin overview!

Palladin Precision Products

Swiss automatic precision turning

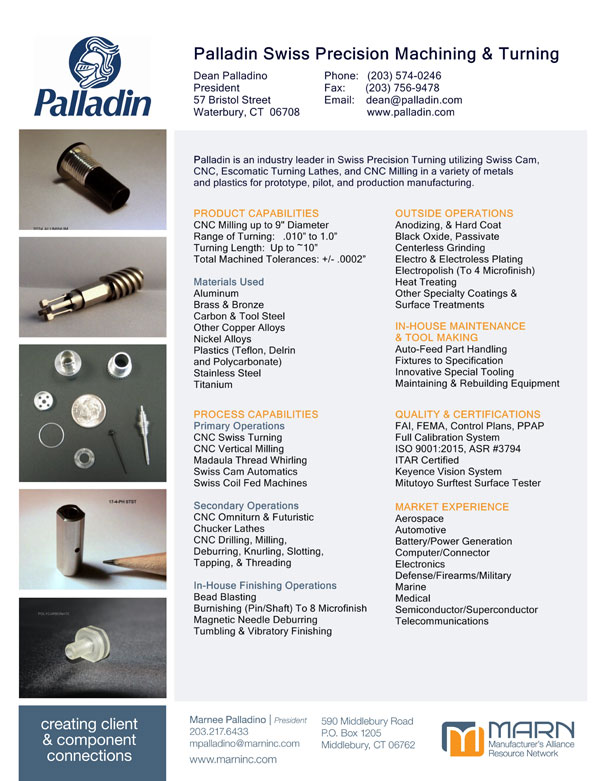

Palladin is an industry leader in Swiss automatic precision turning. Palladin achieves exacting precision utilizing Swiss Cam, CNC, Escomatic Turning Lathes, and CNC Milling in a variety of metals and plastics for prototype, pilot, and production manufacturing. Turning capabilities range from .010” to 1.00” diameter stock.

PRODUCT CAPABILITIES

- CNC Vertical Milling: 18″ x 15″ x 10″

- Range of Turning: .10″ to 1.0″

- Turning Length: up to ~10″

- Total Machined Tolerances: +/- .0002″

MATERIALS

- Aluminum

- Brass

- Bronze

- Carbon & Tool Steel

- Other Copper Alloys

- Nickel Alloys

- Plastics (such as Teflon, Polycarbonate, & Delrin)

- Stainless Steel

- Titanium

Primary operations

- CNC Swiss Machines

- CNC Vertical Milling

- Madula Thread Whirling

- Swiss Cam Automatics

- Swiss Coil Fed Machines

In-house finishing operations

- Bead Blasting

- Burnishing (Pin/Shaft) to 8

- Microfinish

- Magnetic Needle Deburring

- Tumbling & Vibratory Finishing

SECONDARY OPERATIONS

- CNC Omniturn & Futuristic

- Chucker Lathes

- CNC Drilling, Milling, Deburring, Knurling, Tapping, Threading, Slotting

OUTSIDE OPERATIONS

(as specified)

- Heat Treating

- Centerless Grinding

- Electro & Electroless Plating

- Black Oxide, Passavate, Anodizing

- Hard Coat

- Electropolish (To 4 Microfinish)

- Specialty Coatings / Surface Treatments to Spec.

IN-HOUSE MAINTENANCE

& TOOL MAKING

- Maintaining & Rebuilding Equipment

- Innovative Special Tooling

- Auto feed Part Handling

- Fixtures to Specification

MARKETS

- Aerospace

- Automotive

- Battery & Power Generation

- Computer, Connector, & Electronics

- Defense, Firearms, & Military

- Marine

- Medical

- Semiconductor and Superconductor

- Telecommunications

CONTACT

Palladin Precision Products

Palladin Precision Products

57 Bristol Street

Waterbury, CT 06708

Certifications & Quality

ISO 9001

ITAR Registered

Keyence Vision System

Mitutoyo Surftest Surface Tester