Watch this short Laszeray overview!

Laszeray Technology

Injection molding, investment casting, machining, & VA/VE assemblies

Laszeray Technology offers design and manufacturing of world-class products, parts, and tooling for a variety of industries. For nearly two decades, their reputation for exceptional quality has spawned accelerated growth and diversified partnerships that today position Laszeray as an industry leader.

From concept through completion, Laszeray delivers better results through integrated technical design expertise, and through superior manufacturing practices. Laszeray’s world-class competencies in injection molding, tooling, CNC machining, Value Added Engineering and Assembly applications is matched by the company’s ability to deliver accurate, always-on-time service to every client.

PRODUCT CAPABILITIES

Product Design & Engineering Design for Manufacturing

- Injection Molding

- Overmolding

- Two & Three Shot Insert molding

- Material Review & Selection Part Review Process

- Rapid Prototyping – both CNC & Additive Layer

- CNC Machining (36″ x 36″)

PROCESS CAPABILITIES

Primary Operations

- Injection Molding: 65 -1000 Ton

- Multi-Shot (240, 730, & 1000 Ton)

- Insert & Overmolding

- Automated/Robotic PartTrimming

- Robotic Part Handling

- CNC Milling (Haas – 4 & 5 Axis) CNC

- Turning (Haas)

- Investment Casting

Secondary Operations

- Conditioning & Forming

- Wire EDM (Mitsubishi Large Capacity)

- Separating

- Sonic/Ultrasonic & Spin Welding

Value Added/Engineered

& Turnkey Solutions

- Kitting & Sourcing

- Inventory & Stocking

- Assembly & Sub-Assembly

- Packaging & Drop-Shipping

- Box Build & Warehousing

Finishing Operations

- Laser Engraving

- Pad Printing

- Packaging & Labeling

- Surface Finishing & Polishing

- Trimming

OUTSIDE OPERATIONS

- Anodizing

- Heat Treating

- Powder Coating

- Plating

TOOLING (Onsite)

- Injection Molding: Single & Multi Cavity

- Investment Casting

– Wax Injection

– Core & Gate Part

– Multi & Straight Pull

QUALITY ASSURANCE

- Gauging & Precision Measuring

- Material Analysis

- Coordinate Measuring Machine

- Statistical Process Control

- Process Parameters/Standard

- Operating Conditions

- Structured Light Inspection System

MARKETS

- Aerospace & Defense

- Airfoils

- Automotive & Transportation

- Caps & Closures

- Commercial & Consumer Appliances

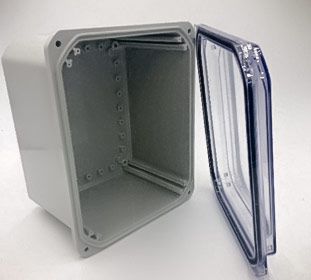

- Electronic Enclosures

- Firearms & Military

- Medical Devices

- Oil & Gas

- Plumbing

- Recreational

- Watercraft

CONTACT

Laszeray Technology

Laszeray Technology, LLC

12315 York Delta Drive

North Royalton, OH 44133

Certifications

ISO 9001

ITAR Registered